About

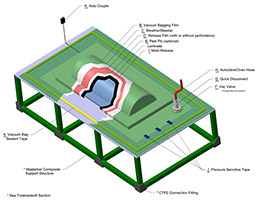

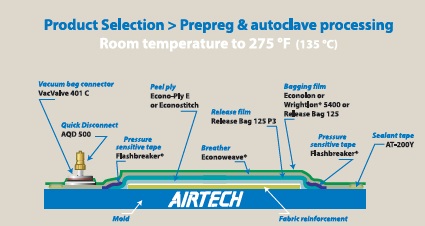

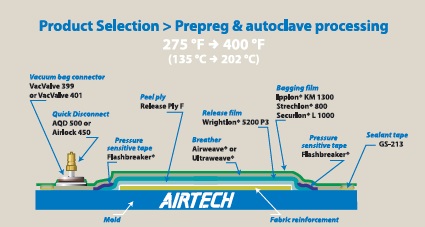

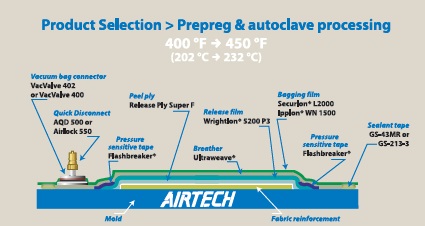

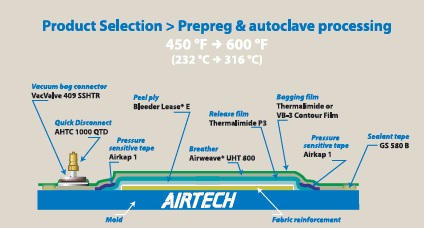

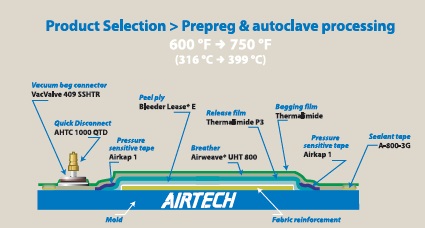

Airtech Asia, Ltd. is a division of Airtech Advanced Materials Group, the largest manufacturer of vacuum bagging and composite tooling materials for prepreg/autoclave, resin infusion, and wet lay-up processes up to 799°F (426°C).

Featured Posts

Contact info

-

Address: No. 161 of Anyuan Road,

Chagugang County, Wuqing District,

301721, Tianjin, P.R. China -

Phone: +86 22 8862 9800